2018年6月29日星期五

two-way straight running conveyor line for can transmission

two-way straight running conveyor line for can transmission-made by Guangzhou Hongjiang Automation Equipment Co., Ltd.

#plastic modular belt conveyor #belt conveyor

2018年6月28日星期四

FAQ - What is Non-powered roller conveyor

#nonpoweredrollerconveyor #theroller #rollerconveyor #gravityrollerconveyor

FAQ - What is Non-powered roller conveyor: FAQ - What is Non-powered roller conveyor

FAQ - What is Non-powered roller conveyor: FAQ - What is Non-powered roller conveyor

2018年6月27日星期三

What Are The Types Of Conveyor

1. Mobile Conveyor It is suitable for conveying, loading, unloading, stacking, and dumping of bulk or packaged grain and small granular materials, and can be used in conjunction with multiple units in series or with other machinery. Can work in open storage. From the rack, transmission, automatic lifting device, support rod, conveyor belt.

2. Inclined Belt conveyors use continuous or intermittent movements of the conveyor belt to transport items under 500 kg or powdered or loaded items. The inclined belt conveyor can be used for continuous conveying in the case of high and low conveying conditions, and can be smoothly connected with the roller conveyor or the chain conveyor.

3. Conveyor Belt Conveyor uses professional tape calculation program software to calculate the tension force of the tape at each turning point. According to these parameters, the tilt angle and idler angle of the roller bracket before and after each turning point and turning point are calculated to ensure that The reliability of the tape running at the turning point.

Flexible Conveyor Chain Plate is basically improved greatly in the traditional chain plate so that the performance of the chain plate has been improved. Transportation products include: belt conveyors, chain conveyors, roller conveyors, mesh belt conveyors, chain conveyors,flexible conveyors.

5. The belt conveyor uses the continuous or intermittent movement of the conveyor belt to transport various items of different weights and weights. It can not only transport all kinds of bulk materials, but also transport various kinds of small boxes such as cartons and packaging bags.

By making multiple rows of one body, the conveyor becomes very wide and forms a differential speed, so that multiple columns become single row in the absence of extrusion, the same can also make a single row into multiple columns and slow walking , resulting in storage.

7. The conveyor is a material handling machine that continuously transports materials on a certain line, also known as a continuous conveyor. Conveyors can be horizontal, inclined, and vertical, or they can be made up of space transmission lines, which are generally fixed. The conveying capacity of the conveyor is large and the distance is long.

8. The belt conveyor is a revolution of the traditional belt conveyor. It overcomes the difficulties of belt conveyor maintenance, the belt is easy to be torn, punctured, corrosion, and provides customers with a safe, fast and easy maintenance. The delivery method. As such conveyors use modular plastic conveyor belts.

9.Stainless steel conveyor structure with stainless steel structure, chain conveyor belt, no exposed fasteners, new design, beautiful appearance; smooth and reliable conveying performance, stepless scheduling, easy to use; used for the appearance of a good, high quality requirements of precision equipment Supporting the use of.

10.Stainless steel mesh belt conveyeradopts stainless steel mesh belt as carrier for conveying, suitable for drying, cooking, frying, dehumidifying, freezing etc. in various food industries, and cooling, spraying, cleaning, draining, etc. in the metal industry. Heat treatment and other processes.

11. Mesh belt conveyors: cartons of beer with mesh chain conveyors, dewatering vegetables with chain conveyors, cans with mesh chain conveyors, battery mesh chain conveyors, tire mesh belt conveyors, vegetable mesh belts Chain Conveyor, Aquatic Net Belt Chain Conveyor, Fruit Net Belt Chain Conveyor, Expanded Food Mesh Belt Chain Conveyor, Meat Food Small Package Net Belt Chain Conveyor, Fruit and Vegetable Net Belt Chain Conveyor, Meat Segmentation Mesh Chain Chain Conveyor.

12. Aluminum alloy mesh belt conveyor adopts aluminum alloy mesh belt as carrier for transportation, applicable to various food, medicine and chemical industries.

2018年6月25日星期一

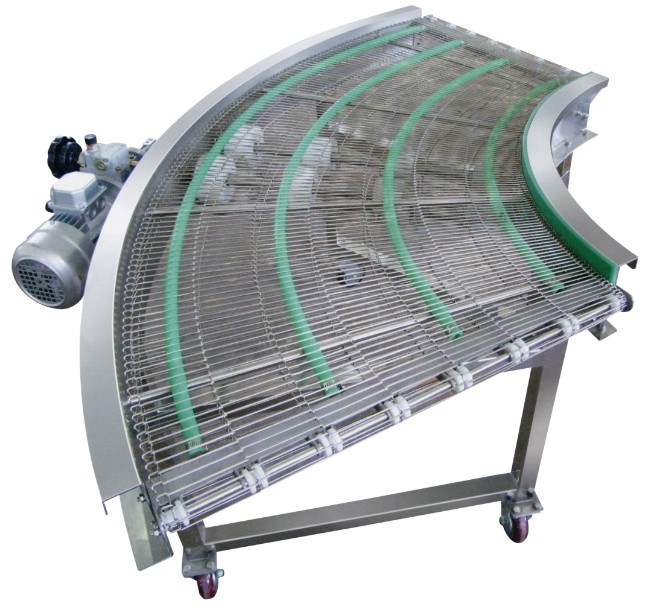

What Is The Feature Of Metal Mesh Belt Conveyor

The metal mesh belt conveyor is a material handling machine that continuously transports materials on a certain line, also called a continuous conveyor, and can be divided into a metal mesh belt type and a metal mesh chain type. Conveyors can be horizontal, inclined, and vertical, or they can be made up of space transmission lines, which are generally fixed. The conveyor has a large conveying capacity and a long distance. It can also complete several process operations at the same time during the conveying process. The mesh belt conveyors are made of carbon steel, 201 stainless steel and 304 stainless steel.

structure type

Horizontal straight-line transportation, lifting and climbing transportation and other forms, the conveyor beltcan be added lifting baffle, side baffle.

Metal mesh belts are used as delivery carriers.

Driving method

Geared motor drive.

Speed mode

Frequency control, variable speed.

Transportation machinery frame material

Stainless steel, carbon steel.

Range of use

Applicable to all industries such as drying, dehumidification, cleaning, quick freezing and other processes.

1, working principle

The conveyor chain is a sleeve roller chain, continuous bucket structure, used for high temperature clinker level, climbing.

2, the main features

◆ Large conveying capacity: The maximum conveying capacity can reach 526m3/h, and the maximum inclination angle can reach 60 degrees. High temperature resistant, capable of conveying materials with a temperature of less than 600 degrees.

◆ The conveyor chain consists of a traction chain, a load-bearing chain, and a forward lap (or reverse lap) hopper. The three parts can be freely loaded and unloaded.

◆ Rolling bearings are used in load-bearing rollers. Rolling friction is used instead of the conventional sliding friction. The running resistance is reduced by 55% to 65%, which greatly reduces the power consumption of the conveyor and has low energy consumption.

◆ The traction chain and load-bearing chain are separated, simplifying the structure, reducing the cost, and facilitating the installation and maintenance.

◆ Long service life: The traction chain uses long pitch, sleeve roller chain, and the parts of the chain are all made of alloy steel materials; after heat treatment, they are wear-resistant. The weight of the conveying part and the material is borne by the load-bearing parts; the chain no longer bears weight and reduces wear.

◆ The layout of the craft is various: It can be horizontal and inclined, and it can also be arranged by multiple stages of horizontal and inclined combination.

3, applicable areas

◆ Widely used in cement, paper, sugar, chemical and other industries. The most suitable for the material slurry type, granular and so on.

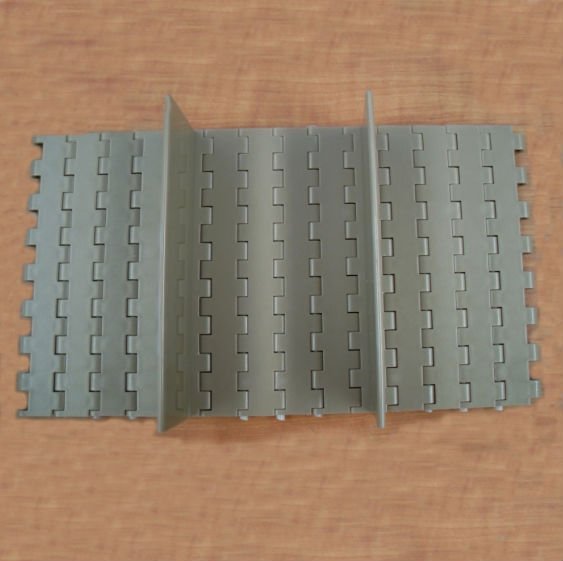

FAQ - Do you know the detail information about plastic chain and modular belt?

FAQ - Do you know the detail information about plastic chain and modular belt?: FAQ - Do you know the detail information about plastic chain and modular belt?

#conveyorbelt #conveyorchain #conveyorbelts #plasticconveyorchain #plasticmodularbelt #conveyor

#conveyorbelt #conveyorchain #conveyorbelts #plasticconveyorchain #plasticmodularbelt #conveyor

2018年6月22日星期五

plastic modular belt elevator inclined conveyor for spinning ball transm...

plastic modular belt elevator inclined conveyor for Spinning ball transmission--made by Guangzhou Hongjiang Automation Equipment Co., Ltd.

plastic modular belt elevator

plastic modular belt conveyor

elevator inclined conveyor for spinning ball transmission

spinning ball conveyor

2018年6月20日星期三

FAQ - What is the computer assembly line

FAQ - What is the computer assembly line: FAQ - What is the computer assembly line

#assemblyline #automationconveyor #conveyor #automationline

#assemblyline #automationconveyor #conveyor #automationline

2018年6月19日星期二

FAQ - What is a single conveyor line?

FAQ - What is a single conveyor line?: FAQ - What is a single conveyor line?

Guangzhou Hongjiang the manufacturer of conveyor and conveyor component

Guangzhou Hongjiang the manufacturer of conveyor and conveyor component

What is a single conveyor line?

One-piece conveyor lineis also called unit synchronization conveyor line. One-piece conveyor line is to make comprehensive and effective use of personnel, equipment, and logistics. There is an organized, planned, and targeted progress. Each unit balances production. In production activities, one batch is used for production batches, and there is no stagnation between the front and back processes. Each process completes a process of self-examination and a process of production is called an assembly line production method, or simply a single conveyor line.

Single-conveyor line features

1. Target management: Targeting the production capacity, industrial engineers set target production capacity for each unit (process) of the product

2. Time management: The time is quantified, and industrial engineering personnel set the target operation time for each unit (process) of the product

3. Fast production of finished products, rapid response to quality problems, zero batch quality accidents

4. Pull forward and pull back: It is different from traditional production methods. Traditional production methods and production lines are passive. It can only wait for the materials, cutting, embroidery, and printing of the front department to determine the normal operation of production, while the single-piece flow produces it. Is active, the previous process must meetthe production line, all for the sake of production. Pushing ahead is not just pushing the water forward. It includes orders, material supply, and product reprocessing. After pulling, it is to meet the needs of customers and pull the entire production and supply chain.

2018年6月17日星期日

Assembly-line for Feedbag powder bags

Assembly-line for Feedbag powder bags--made by Guangzhou Hongjiang Automation Equipment Co., Ltd.

#feedassemblyline #powderbagsconveyorsystem #powderpackagetransmissionline #bagconveyorsystem

2018年6月13日星期三

News - Guangzhou Hongjiang, as the most popular conveyors manufacturer,attended the 2018,6th Dongguan Robotics & Automation Exhibition

News - Guangzhou Hongjiang, as the most popular conveyors manufacturer,attended the 2018,6th Dongguan Robotics & Automation Exhibition: News - Guangzhou Hongjiang, as the most popular conveyors manufacturer,attended the 2018,6th Dongguan Robotics & Automation Exhibition

we will exhibit new type spiral conveyor and conveyor component

#spiralconveyor #screwconveyor #plasticconveyorcomponent #conveyorparts

we will exhibit new type spiral conveyor and conveyor component

#spiralconveyor #screwconveyor #plasticconveyorcomponent #conveyorparts

2018年6月11日星期一

Question And Answer About The Conveyor Design

Question and Answer About the Conveyor

1: The assembly line must always be from left to right or from right to left?

In general, because most people are accustomed to the right hand, the assembly line flows from left to right. However, because of the limitation of the area of some factories, it may cause at least one of the two or more conveyor lines to flow in the opposite direction.

2:U-shaped assembly line is the most appropriate?

Not necessarily, the production line layout must be based on the product's characteristics and craftsmanship.

3: The faster the assembly line, the higher its production capacity?

The level of production capacity should depend on the operating time of the bottleneck process and the fastest working time of each station. If it is forced to increase the speed of the production line, it will cause many problems.

4: Is the assembly line designed to ship products?

not completely. The ultimate goal is still to achieve the "continual value flow" of the product.

5: Why is the production rate just lower at the time of work or shift?

It is a stage of preparation and it is a period of time when problems occur. So the management of the shift is very critical.

6: Should the streamline speed settings be kept constant? Every day?

In the same product category should be constant, in the production of different products on the same line, there will be changes in speed. At the same time, because of the problem of new employees, the line speed will decrease.

7: Pitch mark Can only put one product per cell?

Not necessarily, should be the pursuit of stable production flow

8: The faster the pre-assembly process, the better? Is it better to buffer more inventory?

No, it should be produced on demand. However, the pre-assembly processing speed can be slightly faster than the assembly speed.

9: The assembly line is easy to find backlog, computer can show progress, and the line length reminds employees to do it quickly?

The first two are correct, but the third is not necessarily. In the normal production cycle, it is not appropriate to urge employees. This will cause some unnecessary problems (for example, urging employees to change their hands-on changes, and neglecting the inspections).

10: The line lengther said that someone asked for leave, couldn't line up? If I can't borrow people, can I separate my employees?

First of all, the assembly line cannot strictly complete the follow-up of all assignments. Because there are few people in one area, there will be a decline in production, but not much. Where else does the emergency response occur? Managers do not consider these common problems, then he can open a factory?

11: Is it reasonable for employees to stand in production or sit in production?

Due to product/condition/facilities

12: The container on the streamline should be dedicated or generic. What is his size?

Most general-purpose designs should be designed, and general-purpose special treatment cannot be used.

13: How highly reasonable is the width of the streamline and the height and width of the machine?

According to ergonomic principles, the sitting table is 65~75CM high, the seat is 38~45, the standing table is 85~95CM, the seat is 58~62, and there are 20~30 board feet.

2018年6月8日星期五

stainless steel straight running roller conveyor- made by Guangzhou Hongjiang Automation Equipment Co., Ltd.

stainless steel straight running roller conveyor- made by Guangzhou Hongjiang Automation Equipment Co., Ltd.

https://youtu.be/UGZ9lrtNaTU

https://youtu.be/UGZ9lrtNaTU

2018年6月6日星期三

How To Optimize The Assembly Line

optimization

The assembly line plays an important role in industrial production. Optimizing theassembly line directly affects the quality of products and the efficiency of production. Therefore, it becomes a topic that companies must pay attention to.

1. Optimize the operation time of the first station of the assembly line, and how long it takes to put a board. This is the required input cycle time to meet the production plan volume. However, in practice, the bottleneck station's working time must be greater than the first station, and the first station must not be a bottleneck station. Therefore, the first station may not be completely invested according to the required cycle time, because the bottleneck station has slowed down its speed. Therefore, from the management point of view, it is necessary to require first-stop operators to invest at the required speed. The conveyor belt speed in the assembly line can also be used to calculate the daily output. Here is the formula for the speed of the conveyor belt:

Pitch time of the conveyor belt = day-time work/day production* (1+ defective rate)

Conveyor speed = distance between markers / pitch of the conveyor

The mark distance, the distance between the marks on the assembly line belt, expects the operator to complete the work and place it on the belt line at the speed at which the marks flow; however, the chain line is not marked and the length of the board is used. Marking distance. Why use a conveyor belt? Besides semi-manufactured items, there are also semi-mandatory operators who can perform tasks as planned. However, they do not try to speed things up. They should be calculated according to the above formula.

2. Observe which station on the assembly line is the bottleneck station:

(1) Stations that are always busy;

(2) Always pull the board back to the station;

(3) From the station, there was an interval between the original one and the next.

The above three points are visually perceptible. The second is the use of a stopwatch. The operating time is the longest of all stations.

The operating time of the bottleneck station becomes the cycle time of the actual output of the entire assembly line, and the daily production formula is as follows:

Daily production = actual work time/interval cycle time

Therefore, as long as the on-site cadres can reduce their working hours, they can significantly increase their output. For example, they can use parts to do other stations, use governance tools to save movement, improve the configuration of the operating domain, and so on. However, after the bottleneck station is solved, new bottleneck stations may appear. Therefore, this new bottleneck station will be improved. Therefore, the bottleneck station will continue to improve, and the efficiency of the entire assembly line will increase day by day.

3. Observe the cycle time at the last station of the assembly line, which is the actual output cycle time. The cycle time of this station must be equal to the bottleneck station. From this station, we can calculate the efficiency of this assembly line. The formula is as follows:

Efficiency = input cycle time/actual cycle time = working time at the first station / working time at the last station

Of course, you can use the bottleneck station's operating time to calculate, but it is always simple and practical to observe the last stop.

The number of WIP on the assembly line is equal to:

(Working time at the last stop - Working hours at the first station) * (Working hours on the whole day/Working hours at the last stop)

4. Observation of the farming rate

Activity rate = time spent on work / working hours throughout the day

The so-called movement is an effective line of work on the assembly line. The fact that the operator sits on the seat does not mean that he is at work and that he has to work on the product. Therefore, observe the operator's time at work. However, in reality, it is impossible to measure every operator for the entire day. Therefore, there is a kind of work spot-checking method to simulate measurement. In fact, from time to time, we see what the operator is doing.

5, the assembly line operator sitting on the seat does not mean that he has to work seriously, so the final is to observe the speed of each operator's job, speed is a very abstract concept, light is difficult to compare and quantify from the visual, so Establishing a standard speed in your heart is faster than it is even better. The movements are streamlined, fixed, and rhythmically performed, often with better working speeds, and vice versa. This is easier to observe.

2018年6月5日星期二

What The Advantge, Feature Of The Assembly Line

The advantages of assembly line or conveyor

1. Integrate production process, can arrange a variety of workstations on the assembly line to meet production needs;

2. High scalability, can design the assembly line that meets the product production demand according to the factory's demand;

3. Saving factory production costs can save the number of production workers to a certain extent, achieve a certain degree of automated production, with little investment in the early stage and a high return rate.

Assembly line feature

1. The degree of professionalism in the workplace is high.

2. The process is closed, the work place is arranged in the order of the process, and the labor object makes one-way movement between processes

3. The processing time of each process is the same as the proportion of the number of workplaces in each process.

4. Each process is produced according to a uniform beat. The so-called beat refers to the time interval between the production of two adjacent products.

Assembly line system

According to whether the production object moves, it can be divided into fixed flow production line and mobile flow production line.

According to the number of production varieties, it can be divided into single-type production line and multi-type production line.

According to the continuous degree of production, it can be divided into continuous flow production line and intermittent flow production line.

According to the method of realizing rhythm, it can be divided into forced beat water production line and free beat water production line.

According to the degree of mechanization, it can be divided into three types of hand-made, mechanized and automated production lines.

2018年6月4日星期一

what is assembly line

Assembly line is also called assembly line conveyor. An industrial production method means that each production unit only focuses on the processing of a certain fragment to improve work efficiency and output. According to the assembly line, it can be roughly divided into: belt assembly line and Chain plate, double speed chain, plug-in line, mesh belt line, suspension line and roller conveyor line these seven types of lines. It generally consists of traction elements, load bearing members, drive devices, tensioners, redirection devices, and support elements. The pipeline has high expandability and can be designed according to the needs of the delivery volume, conveying speed, assembly station, auxiliary components (including quick connectors, fans, lights, sockets, crafts,console, 24V power supply, wind batch, etc.

The assembly line is an effective combination of man and machine, which fully reflects the flexibility of the equipment, and it combines the organic combination of the delivery system, accompanying fixtures, on-line special machines, and testing equipment to meet the requirements for the transportation of various product types. With synchronous transmission (forced) or non-synchronous transmission (flexible), according to the choice of configuration, assembly and transport requirements can be achieved.The transport line is indispensable for the mass production of enterprises.

Origin

In 1769, the Englishman Josiah Wedgewood set up the Etruscan ceramics factory and implemented a fine division of labor on the site. He divided the original pottery process completed by one person into dozens of specialized processes. Respectively by the person to complete. In this way, the “potters” in the original sense ceased to exist. What existed was that diggers, mason, earth-workers, and blank makers turned potters into potters’ workers. They must press A fixed work rhythm and labor are subject to unified labor management.

(According to the above information, it can be clearly seen that Wedgwood's working methods can be fully defined as “pipelines.” Another is that Henry Ford invented the assembly line process, which is obviously inaccurate, because Henry Ford Born in 1863 and lived more than ninety years, nearly a century later.

订阅:

评论 (Atom)