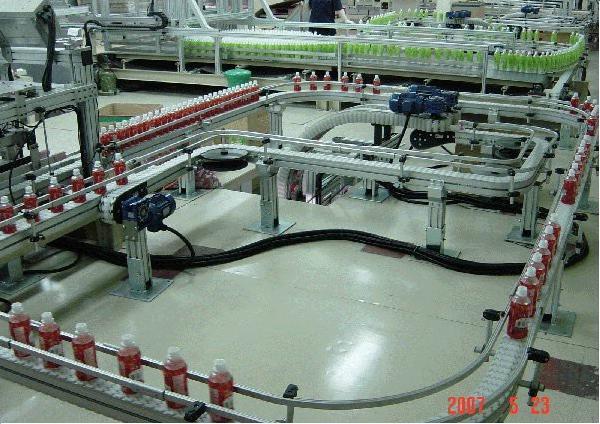

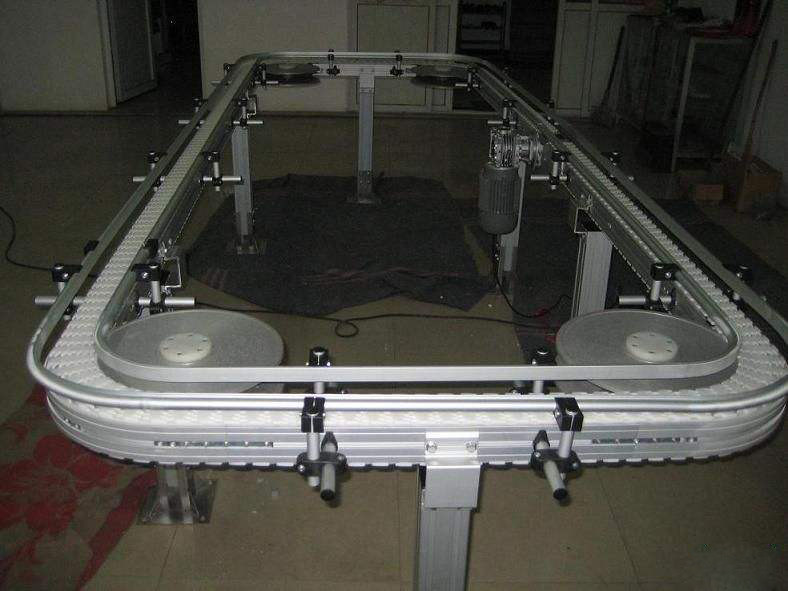

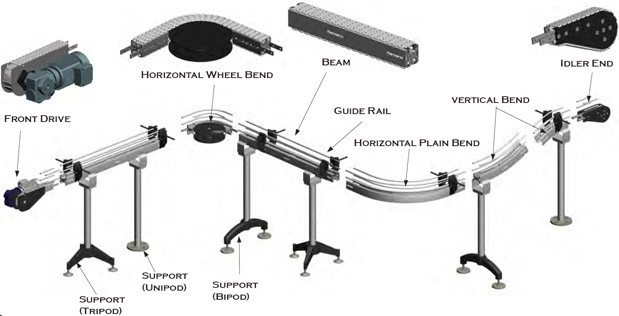

The flexible chain conveyor can automatically carry out the continuous transportation of transportation, distribution and subsequent packaging. It is the best choice for enterprises to improve the efficiency of automated production. In the flexible chain conveyor, the chain plate and motor are more important. The conveyor manufacturer suggested that we use it together. Today we will specifically understand the other important structure of the flexible chain conveyor, the characteristics of the chain plate.

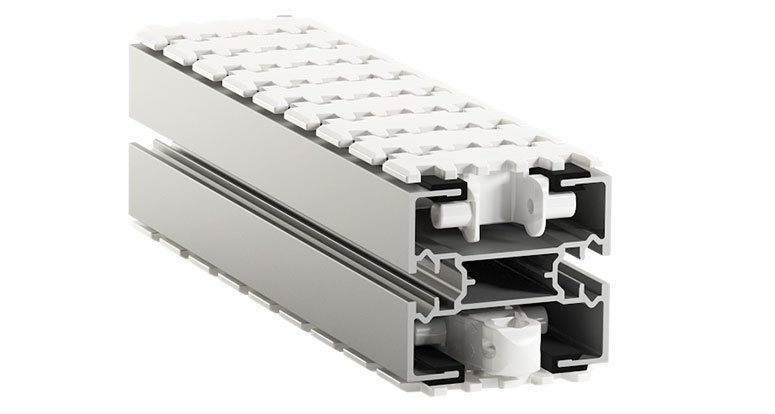

1. The tooth shape of the sprocket

The sprocket tooth shape must ensure that the chain energy-saving smoothly enters and exits the mesh, minimizes the impact and contact stress of the link during the meshing, and is easy to process.

Commonly used sprocket face tooth profile. It is composed of three arcs aa, ab, cd and a straight line bc, referred to as a three arc-linear tooth shape. The tooth shape is machined with a standard tool. It is not necessary to draw the end face tooth shape on the sprocket work diagram. It only needs to be marked on the drawing; the tooth shape is manufactured according to the 3RGB1244-85 specification; however, the axial tooth profile of the sprocket should be drawn. The dimensions are referred to the design manual.

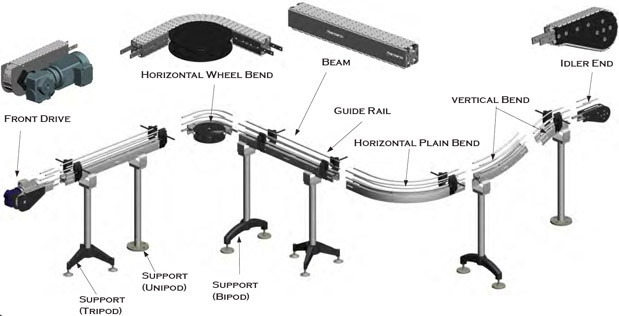

2. Sprocket structure

Commonly used sprocket structure. The small-diameter sprocket is generally made in one piece, and the medium-diameter sprocket is mostly made into a spoke type. In order to facilitate handling, loading and weight reduction, a hole is formed in the web, and the large-diameter sprocket can be made into a combination. Rings and wheel cores can be made from different materials! For example, C45, stainless steel and other materials.

3. Sprocket material

The sprocket material should ensure that the teeth have sufficient strength and wear resistance, so the sprocket tooth surface is generally heat treated to achieve a certain hardness.

We now understand the characteristics of the chain conveyor sprocket, which is also very helpful for us to choose the sprocket of the chain conveyor.