#transmissionequipment #transportaionequipmentindustry

The equipment manufacturing industry is a manufacturing industry that provides production technology and equipment for the national economy and national defense construction. The transportation equipment is the driving force for the production and transportation of the manufacturing industry. It is also part of the manufacturing equipment. It can be said that the transmission equipment is the driving force for the equipment manufacturing industry to deliver products. The core component of the transportation power of the industry is that the transportation equipment is the basis for the development of the national economy, especially the industrial development. Establishing a strong equipment manufacturing industry is the fundamental guarantee for improving China's overall national strength and realizing industrialization. Similarly, transportation equipment plays a vital role in building a strong equipment manufacturing industry and improving China's comprehensive national industrialization.

The Ministry of Industry and Information Technology reported that the equipment manufacturing industry accounts for more than 20% of the national industrial economic indicators. The export value of equipment manufacturing products accounted for 25.46% of the total foreign trade exports. In 2018, the equipment manufacturing industry is an industry that is seriously affected by the current economic situation. The transportation equipment industry is also seriously affected by the market economy. According to the statistics of the National Bureau of Statistics, the added value of the industry increased by 8.4% year-on-year last year, down 6.7 percentage points year-on-year, which is significantly lower than that of other scale industries. “The above problems are mainly due to the obvious decline in orders, the sharp decline in export growth, and the small profitability of enterprises. increase."

Looking forward to the new 2018, China proposes to continue to accelerate the transformation of innovation drive, structural adjustment and development mode, and further promote industrialization, informationization, urbanization, and agricultural modernization. The chief engineer of the Ministry of Industry and Information Technology pointed out that the external macro-policies of the equipment manufacturing industry and the economic, technological and social environment are still improving. In this great form, the transportation equipment industry took this economic express train to the spring, and advanced to the industrialization, informationization, urbanization and agricultural modernization proposed by the "two sessions."

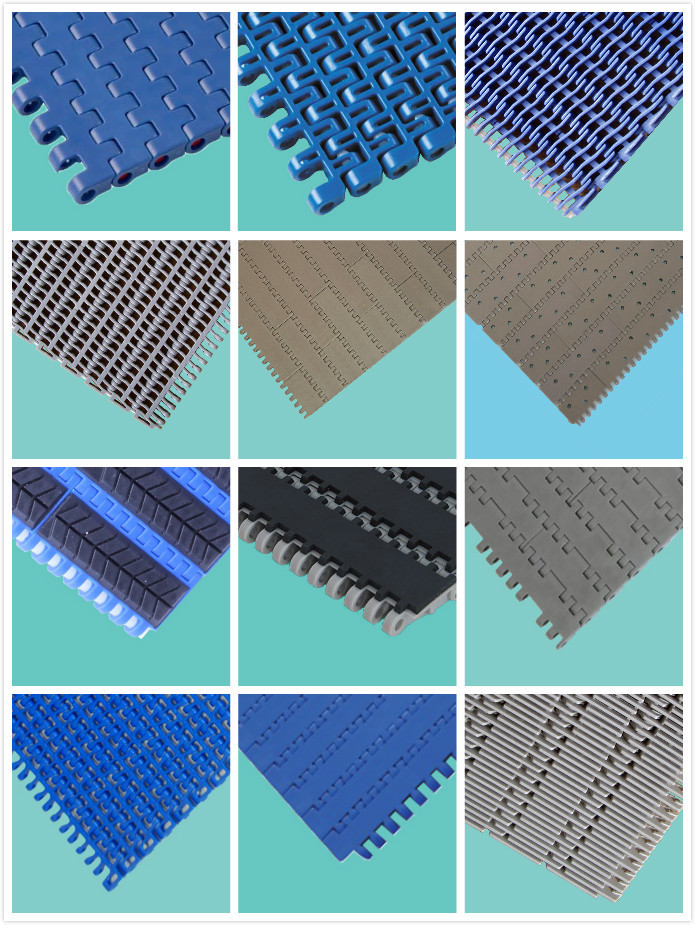

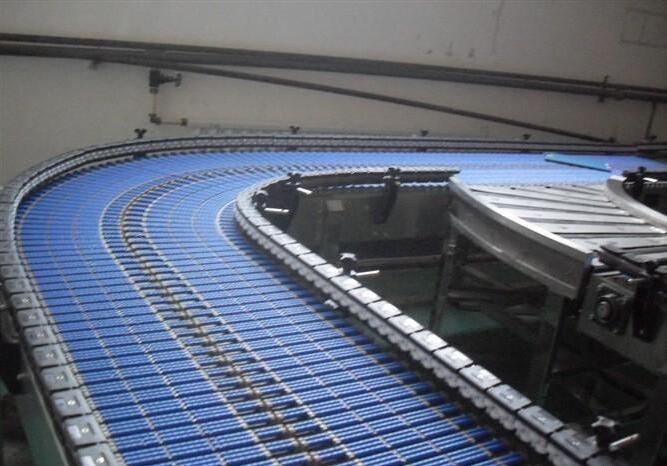

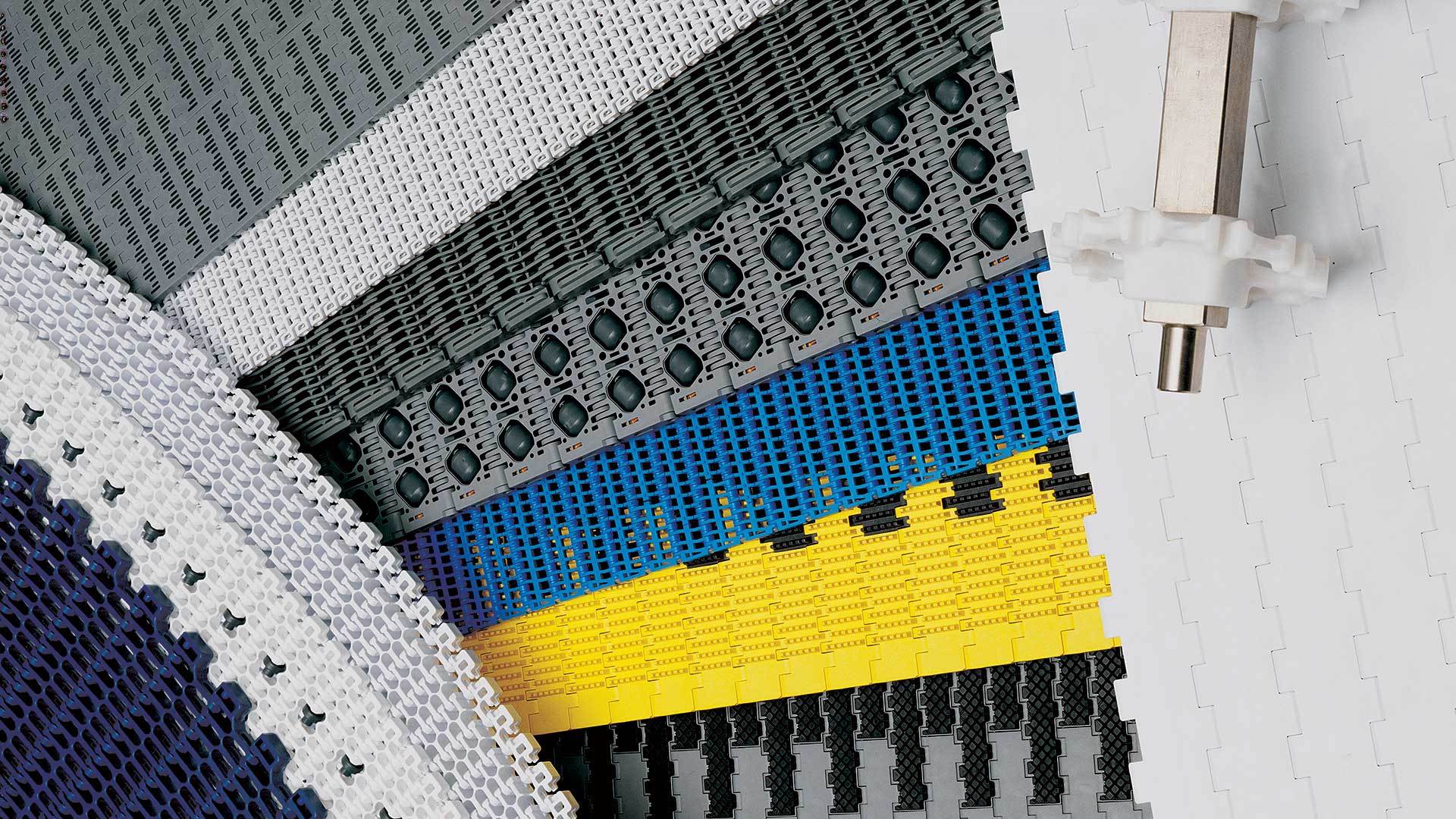

“In the past few years, with the continuous upgrading of the transportation equipment industry, the small-scale, light-weight and single-stage primary manufacturing has not met the market demand, and the transportation equipment enterprises must go to the high-end manufacturing of large-scale heavy-duty and total integration in order to survive. "High-end conveyor equipment manufacturing needs scientific and technological support, integrating new technologies and new ideas into the manufacturing industry, and independently researching and developing equipment innovation market. This is the transformation direction of our modern transportation equipment industry.

Relevant experts pointed out that the transportation equipment industry only continues to accelerate the transformation of its products, structural adjustment and development mode, and further promote industrialization, informationization, urbanization, agricultural modernization, and external macroeconomic policies and economic, technological and development of the transportation equipment industry. In many aspects of the social environment, the transportation equipment industry in 2018 will continue to develop in a good direction. Therefore, experts believe that the development of the transportation equipment industry is still focused on its own technical strength, supported by new technologies, to improve the overall level of domestic transportation equipment manufacturing, especially in the field of high-end transportation equipment needs to further narrow the gap with developed countries. To improve the independent capacity of industrial production.

The upgrade of transportation equipment manufacturing is the key to realizing the transformation and upgrading of the domestic transportation equipment industry. Only the domestic transportation equipment industry can achieve breakthroughs in core technology and core equipment to promote Chinese transportation equipment to the international market. Only the upgrading of the transportation equipment industry can push China's manufacturing industry to a new future, and truly push China to the road of industrial power.