2018年11月29日星期四

Plastic flat top flexible chain curved conveyor

#turningbeltconveyor #90degreebeltconveyordesign #flexibleaugerconveyor #dragchainconveyorsuppliers #chainconveyorsmanufacturers

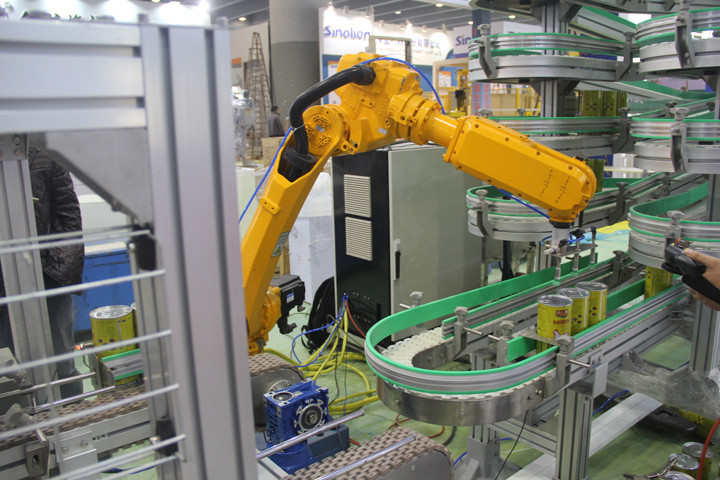

Plastic flat top flexible chain curved conveyor --- Guangzhou Hongjiang customized conveyor

How To Improve The Automation Of The Belt Conveyor?

#modularbeltconveyors #automatedtransportation #meshbeltconveyor #beltconveyor #metalconveyorbelt #meshbeltconveyors #metalconveying

There are more and more environments for conveying operations in modern production, and the most advantageous features of modular belt conveyors have been adopted. In this case, you must understand whether the belt conveyor is suitable for your own product delivery, and do not blindly purchase. The mesh belt conveyor is more suitable for the conveying of shaped objects, and is most suitable for product cleaning, conveying and drying. The advantage of the mesh belt conveyor is the metal conveyor beltstructure, corrosion resistance, high temperature resistance, low cost and long service life, which also makes the mesh belt conveyor suitable for a variety of material transportation advantages.

Mesh belt conveyors are used more and more in drying, cleaning and food industries, which is not unrelated to the unique technical characteristics of mesh belt conveyors. Such as long conveying distance, transparent conveyor belt, corrosion resistance, high temperature resistance, are the technical characteristics of the belt conveyor, which is unmatched by other methods, because with these, the belt conveyor is also more widely transported. The field is used, from the original single food industry to the current industrial cleaning, product drying are equipped with mesh belt conveyors.

The current belt conveyor has been extended from a single food delivery to drying, conveying, cleaning, metal conveying, automated transportation and many other working environments. In many conveying operations, the old-fashioned mesh belt conveyor can no longer meet the matching with other equipment. The functions such as synchronization, load-bearing induction and intermittent transportation need to be completed by the belt conveyor. At this time, the degree of automation of the belt conveyor is high. It is especially important. In order to match the advanced equipment with the belt conveyor, it is necessary to improve the degree of automation. Only when the automatic control and automatic transmission are achieved, the belt conveyor can take a step higher.

Talking about mesh belt conveyors, people working in the transportation industry are very familiar with the conveyor belts in the working environment of food, fruits and vegetables, drying, cleaning and so on. I feel that there are quite a few belt conveyors on the Internet, but there is still more space for the belt conveyor in the transportation industry. In order to expand the use of mesh belt conveyors, there are still many places to break through. The main breakthrough is the automation control, which is the main reason why the belt conveyor can not move to the high end. There is also a need to break through like the appearance of work, do not say that it can be used on the line does not matter. As long as these configurations of the belt conveyor are raised, it will have more room for use.

With the increase in the use of mesh belt conveyors, the problem of the configuration of the belt conveyors needs to be taken seriously. Whether it is transporting in the natural environment or drying, cleaning and conveying, the belt conveyor should have basic configuration such as speed regulation, tensioning and emergency stop. Other configurations include: induction, intermittent, remote control, alarm Wait. Among them, speed regulation and tensioning and emergency stop are the most important, and it is also the most basic configuration of the mesh belt conveyor. Nowadays, the speed regulation and tensioning are mostly selected for induction speed regulation and automatic tensioning. Only with these is a normal mesh belt conveyor.

2018年11月28日星期三

What Is The Key Issue For Toothed Chain Sealing And Lubrication?

#conveyorequipment #toothedchain #toothedchainassembly #flexibleconveyor

Sealing and lubrication are the key issues in the design of the toothed chain assembly, because most of the failure of the toothed chain assembly is due to the early failure of the bearing due to the entry of the lubricating medium into the debris, the sealing structure and the original due to lubrication and heat dissipation problems. Early failure. Therefore, the flexible conveyor seal and lubrication can not be considered separately, but a purposeful and foreseeable deployment design according to the specific structure and use environment. At present, the sealing method of thetoothed chain assembly can be divided into the following types:

1. Rotary oil seal seal This seal is easy to realize, simple in structure and processing, convenient in disassembly and assembly, and low in cost. The disadvantage is poor sealing ability and low service life. Therefore, most of them are applied to small scraper conveyor equipment.

2, floating seal floating seal has the advantages of high sealing performance and long service life. Widely used in scraper sprocket assemblies. At present, most of the domestic use of two types of floating seals: 0-ring type and rectangular (diamond) ring type. 0-ring floating seal with automatic centering. Adapt to occasions with large angular deviations. The rectangular (diamond) ring type floating seal has the advantages of inaccurate axial deviation, simple sealing chamber shape and easy processing and assembly. Both types of floating seals require: the quality of the rubber ring is stable, especially the elasticity is excellent, and has good adaptability; for the iron ring, the flatness of the bright band is required to be high, and the wear resistance and heat resistance are good.

3, labyrinth, felt ring, dust ring auxiliary seal labyrinth, felt ring, dust ring is a necessary auxiliary link, flexible conveyor should be actively arranged when space allows. This promotes the sealing of the sprocket assembly. In fact, the main idea of sealing and dustproof should be: dust is worse than dust. If you can use a good structure to avoid the location of the polluted environment such as coal dust, it will have a multiplier effect on the seal.

In summary, the problem of toothed chain sealing and lubrication needs to be considered.

2018年11月26日星期一

FAQ - Have you passed CE certification?

#conveyormachineequipment #guangzhouhongjiang #conveyorandconveyorcomponentmanufacturer #CEcertificationConveyor

FAQ - Have you passed CE certification?: FAQ - Have you passed CE certification?

FAQ - Have you passed CE certification?: FAQ - Have you passed CE certification?

News - Four major risks in China's small and medium-sized stainless steel mesh belt enterprises

#stainlesssteelmeshbelt #networkbeltandnetchain #packagingmachineryparts #stainlesssteelchain #packagingsystem

News - Four major risks in China's small and medium-sized stainless steel mesh belt enterprises: News - Four major risks in China's small and medium-sized stainless steel mesh belt enterprises

News - Four major risks in China's small and medium-sized stainless steel mesh belt enterprises: News - Four major risks in China's small and medium-sized stainless steel mesh belt enterprises

2018年11月23日星期五

roller conveyor & PVC belt conveyor material handling conveyor system

#rollerconveyorline #PVCbeltconveyor #materialhandlingconveyorsystem

#bottletransmissionconveyorline

2018年11月21日星期三

How To Determine The Chain Is Scrapped?

#mechanicalconveyorequipment #platechain #conveyorlineplatechain #conveyorsprocket #conveyorchain

Mechanical conveyor equipment plays an important role in the work, and the conveyor chain is one of the most important parts in the equipment. The plate chain is also a kind of chain and also plays an important role. If the plate chain takes too long, it will cause such problems. Then how to judge the scrapping of the chain?

The general rule of the plate chain is judged from the following aspects: First, the operator should be clear that the wear value allowed by the plate chain is limited. Generally speaking, it cannot be higher than the diameter of the ring chain bar. Tenth. The second point is to see the degree of distortion of the main ring of the main chain of the plate chain. If it is greater than 10 degrees, it will be scrapped. Of course, this should start from the uncurved plane above the main ring. If the chain of the plate chain is used for a long time, cracks, bends, etc. will occur. If it cannot be removed after being removed, it can no longer be used, and it is counted as scrap.

Once the conveyor line plate chain has a problem, it will cause a lot of trouble for production. Then we must do daily maintenance and maintenance in our lives, and strive to reduce equipment damage. Jin Hengli usually does this. First of all, when installing the conveyor sprocket on the shaft, make sure that there is no swing and inclination. When the same drive assembly is not used, the rotary shaft should be in the same horizontal plane. If there is deviation, it will be Let the professional technicians carry out the repairs.

The tightness of the plate chain should be appropriate. It should not be too tight or too loose. If the chain is too tight, the power of the device will increase and the consumption will be excessive. If it is too loose, the device will easily jump or even be unchained. Chains that have been used for a long time should not be mixed with new ones to avoid impact when used and to break the chain.

2018年11月20日星期二

#toothedchainplate #chaingear #toothedchain

Toothed chain plate is an important mechanical root piece used throughout. It is mainly used in high speed, heavy load, low noise and large center distance. Its transmission function is better than toothed belt drive, gear transmission and chain. Transmission, so the gear of the toothed chain plays an important role, but if the gear of the toothed chain fails, it will affect its mission efficiency, so let us first understand the way the lower gear chain gear fails.

1. Tooth surface wear: Regarding open gear transmission or closed gear transmission with unclean lubricating oil, because of the relative sliding between the tooth surfaces, some hard abrasive grains enter the conflicting appearance, and then the tooth profile is changed. The side gap is increased, so that the excessive gear thinning causes the tooth to break. Under normal conditions, only when the abrasive grains are mixed in the lubricating oil, the wear of the tooth surface will be caused during operation.

2. Tooth surface gluing: In the gear transmission of high speed and heavy load, due to the conflicting force between the tooth surfaces, the relative speed is large, causing the temperature in the meshing zone to be too high. Once the lubrication condition is poor, the oil film between the tooth surfaces will disappear. The metal appearance of the two teeth is directly touched and then bonded to each other. When the two tooth surfaces continue to move relative to each other, the harder tooth surface tears part of the data on the softer tooth surface in the sliding direction to form a groove.

3. Weak pitting: When two teeth are engaged with each other, the effect force and counter-effect between the tooth surfaces cause the contact stress on the outer surface of the two missions, because the orientation of the meshing point is changed, and the gear is made periodically. The movement, so the touch stress is changed by the pulsating cycle. For a long time under the effect of such alternating touch stress, a small crack will appear at the tooth mark of the tooth surface. Following the passage of time, the crack gradually expands laterally in the surface layer, and the crack forms a ring shape, so that the tooth teeth A small area of spalling occurs on the exterior to form some tired shallow pits.

4, the tooth broken: in the operation of the load bearing gear, like the cantilever beam, the root of the pulse of the periodic stress beyond the fatigue limit of the gear data, will crack at the root, and gradually expand, when the rest Broken teeth can occur when the transmission load cannot be tolerated. Gears can cause broken teeth due to severe impact, partial load and uneven material in the mission.

5. Plastic deformation of the tooth surface: Under the impact load or heavy load, the tooth surface is prone to partial plastic deformation, and then the curved surface of the involute tooth profile is deformed.

2018年11月18日星期日

Do You Know These Information About The Tank Chain And Draging Case Chain

#conveyorchain #theassemblyline #transportationequipmentindustry #tankchain #dragingcasechain #dragingcasechainconveyor #dragchain

Introduction to the tank chain/draging case chain, the world's first conveyor chain appeared in Germany in the middle of the last century, the German Jiabaolai company discovered the market, the inventor of the conveyor line drag chain is called Dr Gilbert. Waninger's German professor, Jiabaolai Company at that time, keenly discovered that the towline will have great development in the future, and its invention will have great demand. So in the second year of the invention, they began to make full efforts. The market launched the first towline, which played an indelible role in the rapid spread of the assembly line to the world, and also provided a powerful opportunity for the development of the transportation equipment industryat that time.

The draging case chain conveyor is a combination of many unit chains. Its shape resembles a tank chain. Each unit chain is made up of a combination of upper and lower cover plates and left and right chain plates. It can rotate the link very freely. Each node of the chain can be easily disassembled and opened, and if necessary, separate the space in the chain with a separator.

In the same parameter model of the drag chain, its outer height, inner height, and pitch are the same, and the bending radius and inner width of the drag chain can be differently selected according to different needs.

The towline is widely used in the machinery industry, and is generally used in lifting and transportation equipment, glass machinery, robots, door and window machinery, injection molding machines, control machine tools, electronic equipment, stone machinery, and automated warehouses. It is characterized by easy installation and maintenance, oil resistance, salt resistance, acid resistance, alkali resistance, wear resistance, low operation noise, long operating life, open sections of the towline, high speed movement and a little acceleration. The acceleration is generally determined by the situation. It is also suitable for the environment of repeated motion, and can play a traction and protection function for the built-in cable, oil pipe, air pipe, water pipe and the like.

Tow chains generally use high toughness, high elasticity, wear resistance, high temperature resistance and pressure load resistance materials, which are generally made of reinforced nylon or POM.

2018年11月16日星期五

High-rise chain plate screw conveyor

#ScrewConveyorTypeandConveyorSystemStructure #spiralconveyorsale #highrisechainplatescrewconveyor #plastichainspiralconveyor

2018年11月14日星期三

Why Is The Chain Rusted?

#SSchain #conveyorchain #Guangzhouhongjiang #stainlesssteelchain #stainlessteelchainconveyor #stainlessteelchainconveyormanufacturer

Many people know about the S.S chain. This is a part of many equipment that plays the role of a transmission. However, sometimes people find that the chain is actually rusted, which will affect the quality of the chain. Many people want to figure out why the chain is rusted. Then today we will discuss the reasons for chain corrosion.

1. In the process of producing the conveyor chain, the enterprise does not strictly carry out anti-rust treatment on the chain parts in the processing process and the finished chain products after the cleaning rust prevention regulations and the oil seal anti-rust packaging requirements. If the chain is in contact with corrosive liquids or gases.

2. The quality of anti-rust lubricants and cleaning kerosene used by enterprises in production cannot meet the requirements of process technology.

3. As the price of chain steel drops and then falls, the material of the chain steel gradually declines. For example, the content of non-metallic impurities in steel is high (the increase of sulfur content in steel makes the corrosion resistance of the material itself decrease), the deviation of metallographic structure and so on. The source of the chain steel used by the production enterprises is more complicated, and the quality of the steel is even more.

4. Some enterprises have poor environmental conditions, high levels of harmful substances in the air, and too little turnover space, making it difficult to carry out effective anti-rust treatment. Coupled with the hot weather, production workers violate the anti-rust procedures and so on.

Guangzhou Hongjiang can provide you the best quality stainless steel chain. You can also customized the chain material by yourself.

2018年11月12日星期一

The Advantages Of Plastic Hoppers

#plastichoppers #foodverticalconveyor #plasticbuckets

#plasticfoodgradehopper #foodverticalplasticbucketconveyor

#plasticfoodgradehopper #foodverticalplasticbucketconveyor

The hopper is actually a very common food vertical conveyor accessory, and is divided into different types according to different materials, such as plastic hopper, nylon hopper and so on. Although there are many types of hoppers, plastic hoppers are very popular, and many people are very confused about the reasons for the popularity of plastic hoppers. Here is a brief introduction to the advantages of plastic buckets.

1. Good wear resistance, service life is higher than steel hopper, and wear is one of the main failure modes of the hopper. Today's plastic hoppers attach great importance to this problem. In the formulation of raw materials, there are unique wear-resistant ingredients, qualified products produced by professional manufacturers, and also passed the test of local quality supervision and inspection stations and issued test reports. The wear resistance of a good plastic hopper can reach 7500 of A3 steel. Since the thickness of plastic hopper is generally 3 times that of steel bucket, theoretically, the service life of bucket hoist plastic hopper should be 2 of steel hopper. More than double.

2, good flexibility, does not damage the particulate material, plastic hopper due to its unique flexibility, can greatly reduce the damage rate of the material being lifted. Especially in rice processing plants, it is often necessary to upgrade a lot. Therefore, the broken rice produced by the hoist has a considerable proportion in the whole rice milling process. In the aspect of raw grain shredding, the hopper of plastic hopper is corrosion-resistant and has good low temperature, especially suitable for damp, cold and warm environment and intermittent use.

How The Adjustment Foot Helps The Conveyor To Master The Balance?

#adjustingthefoot #conveyorchains #conveyors #conveyingequipment #conveyorequipment #adjustmentfeet

Adjusting the foot is a very common accessory. It has a wide range of applications. It can be used on both the equipment of the production enterprise and the household appliances in the home, such as conveyors. Sometimes it will not be placed when it is placed. Stable, this time you need to adjust your feet to help.

The biggest feature of this accessory is that it can adjust the height. There is a screw hole in the middle of the adjustment foot. Then adjust the length of the screw to adjust the height of the device.

The adjustment feet are also often used in production enterprises, such as conveyor chains or conveyors. They are used constantly. The conveyor equipment is constantly working. The equipment will have amplitude. The stability of the bottom is very important, otherwise it will cause the side. Turning over, with adjustment feet, adjusting unstable places at any time is necessary for equipment and production.

There are many kinds of materials for adjusting the feet. There are plastic and stainless steel. Generally, the households use plastic materials. The enterprises use stainless steel for the sake of firmness. After all, the bearing is much more important. On some coal conveying equipment, Be sure to use the hardness of the adjustment foot to transport the coal to the destination smoothly.

When using the adjustment foot, the clockwise torsion is lowered, and the counterclockwise rotation is to increase. After the adjustment is completed, the locknut must be tightened to avoid shaking and instability of the device. It is best to check if the height of the diagonal adjustment feet is the same, and keep the same level high and smooth.

The price of the adjustment foot is related to the material. The price of the plastic will be slightly lower, then the price of the stainless steel will be higher. The purchaser should purchase according to the production needs, but must buy a good reputation product, although it is an accessory, but in It also plays a big role in the work, so it cannot be ignored.

2018年11月9日星期五

Guangzhou Hongjiang carton automation asssembly line testing

#cartonautomationassemblyline #foodbeveragefactoryassemblyline #cartonpackingline #factoryautomationassemblypackingsystem

https://youtu.be/TXAoJHMmVWE

https://youtu.be/TXAoJHMmVWE

2018年11月8日星期四

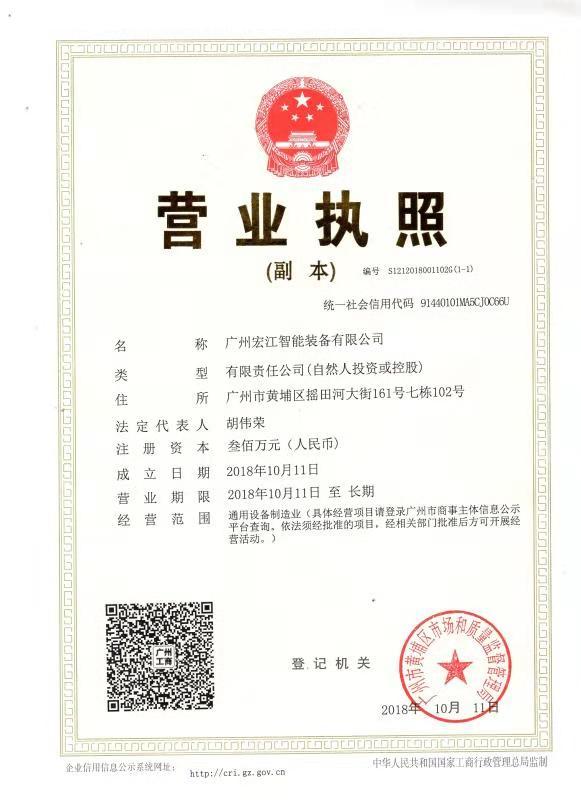

Guangzhou Hongjiang Intelligent Equipment Co., Ltd.

Dear customers, due to business expansion, on October 11, 2018, Guangzhou Hongjiang Automation Equipment Co., Ltd. officially changed its name to Guangzhou Hongjiang Intelligent Equipment Co., Ltd.

The company officially relocated to No. 102, Building 7, No. 161, Shatianhe Street, Huangpu District, Guangzhou.

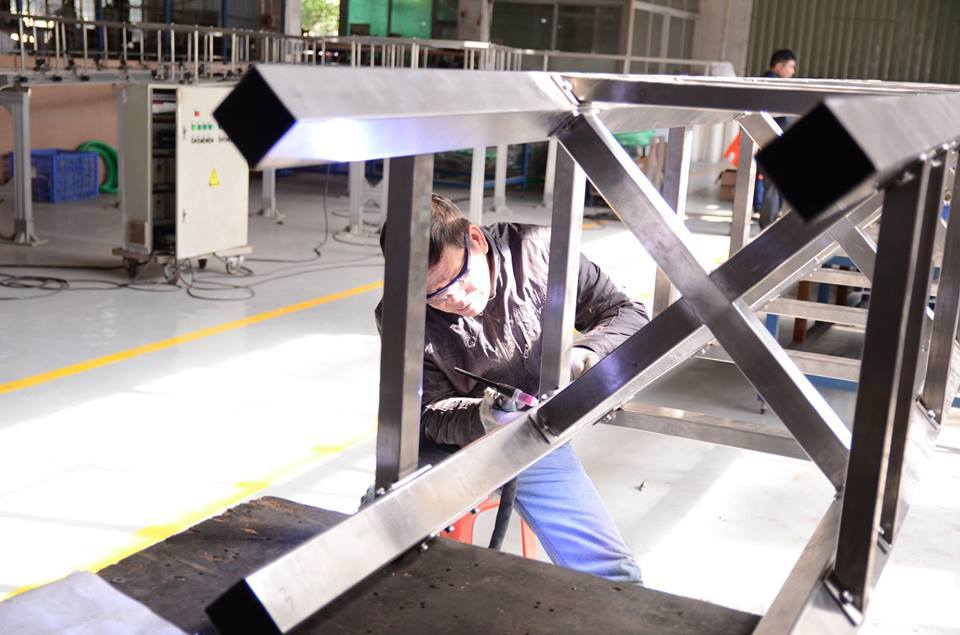

Let us now take a look at our new company.

|  |  |

The workshop is spacious, clean and tidy.

|  |  |  |

The warehouses are neatly arranged and everything is neat and orderly.

We will continue to provide you with more affordable products. Warmly welcome new and old customers to visit.

If you need automation assembly line , conveyor machine or plastic conveyor accessories, please contact us.

2018年11月6日星期二

Where Can I Buy Plastic Chains?

#cheapconveyorbelt #chineseconveyorbeltmanufacturer #lightdutyconveyorchain #marplasticconveyorchain #plasticcrateconveyorchain #plastictopchains

Plastic chains are used in many industries, such as electronics, food, and transportation. In addition, the warning chain applied to urban intersection lanes, construction areas and other places is also one of them. As the application of this product becomes wider and wider, the demand is increasing. In addition to the old factories of their own cooperative companies for many years, many other factories have also demanded them. And those factories that have demand for products may not be very clear about the channels of purchase. So where can I buy this product?

There are a lot of manufacturers in the production of plastic modular chains, and there will be a lot of information when you search for keywords on the Internet. However, although there are many suppliers, you can't just choose something, so as not to be deceived. After all, the network environment is mixed, and if it is rushed to cooperate, it is very likely that the payment will not be received, or even if the quality of the product is not received, the return of the door will be impossible to use, which will have serious consequences. Therefore, if you want to buy this product, it is good to first look at where the companies that need this product are purchased from.

In general, the more people who purchase, the more reliable the manufacturer is, and there are certain advantages in the quality and service of the product itself. If you don't know the purchasing channels of the surrounding companies, it doesn't matter. With your own strength, you can also find manufacturers that provide high quality and low price products.

The easy way is to search the Internet and find a factory with a long history. This kind of factory can survive for so long, and it certainly proves to be safe and reliable, so you can purchase it with confidence. Other new factories that are not too long in history can produce excellent plastic chain products if the equipment is advanced and the reputation is good.

Guangzhou Hongjiang is the manufacturer of plastic chain with over 22 years history. Hongjiang can provide you the best quality and good price product.

Do You Know About Automated Assembly Line Installation And Commissioning?

The automated assembly line is a typical mechatronics device in a broad sense. It involves teaching and internships in related fields such as electromechanical automation and mechatronics. The structure used in the automated assembly line is the profile structure. The installation process of the automated assembly line is divided into: multi-station assembly, well feeding, cutting processing, pneumatic mechanical manual handling workstation, corresponding power module, PLC template, button template and industrial special sensor detection unit. The communication technology used in the automated assembly line system is the PLC industrial network communication technology, through which the linkage of the system can be realized. The process of inspection, feeding, assembly, handling, sorting and transportation in the industrial automation assembly is reproduced objectively and objectively. The automated assembly line is close to the industrial manufacturing site, and on this basis, the teaching and training are specifically designed scientifically. This can strengthen the installation and commissioning of the automated assembly line, better meet the needs of industrial manufacturing, and can better meet the on-site conditions of mechatronics and automation students' internship training.

Through this kind of simulation learning, the team ability and installation and debugging ability of the staff can be exercised, and the work ability and safety awareness of the staff can be improved. The simulation learning of the automated assembly line can also meet the requirements of the core skills training of the automation technology professional. Highlight the comprehensive application of technology.

The installation and commissioning of the automated assembly line is more suitable than the requirements of the industrial city. It is a relatively common automated assembly line. From the actual industrial site, it fully considers the requirements of industrial design and aesthetics, and integrates many technologies such as mechanical, pneumatic, electrical, and sensing equipment.

The overall structure of the automated assembly line is disassembled and open, and it has a relatively obvious disassembly and assembly training function. It can be disassembled to every part and small screws, which makes it a good job to train the hands of the staff and interns, so that they can adapt to work faster. The automated assembly line has a relatively strong reorganization capability and can be assembled and assembled with different modules according to different industrial requirements.

The components and functions of the automated assembly line:

The whole of the automated assembly line consists of thirteen parts. It is divided into a material station, a processing station and an assembly station. In addition, there are handling stations, finished product sorting stations, inverter modules, power modules, PLC modules, as well as button modules and motor driver modules, as well as various sensors, and finally It is equipped with a solenoid valve, an interface for import and export, and the like. Through these parts, the automated assembly line can perform both the loading and processing of the production, as well as the sorting, assembly and transportation processes.

1, the composition of the handling station and specific functions

The main function of the handling station is to carry various accessories that need to be processed. The components of the handling station generally include stepper motor drives, mechanical components, linear guides, positioning and forming switches, including brackets and four-degree-of-freedom handling robots.

2, the composition of the material station and specific functions

The main role of the material station is to provide raw materials for the production activities of the automated assembly line. It is generally composed of a well type workpiece library, a material table, a push cylinder, and a solenoid valve, a photoelectric sensor and a bracket, and various mechanical components.

2018年11月5日星期一

How To Maintain A Food Grade Conveyor Belt?

#foodconveyorbelt #conveyor #foodgradebeltconveyors #foodgradeconveyorbelts #conveyorbelt #foodline

The food conveyor belt is an important part of the food-grade belt conveyor, which accounts for more than half of the total cost of the conveyor. Therefore, it is especially important for the conveyor belt of the food line to protect and maintain the daily maintenance.

The maintenance and protection of food grade conveyor belts are mainly the following:

1. The feeding direction should be in the running direction of the tape. In order to reduce the impact on the tape when the material falls, the chute should be adopted to reduce the material drop interval; the tape receiving section should shorten the idler interval and use the buffer roller as the leakage material. The belt is compliant with a soft and moderate baffle plate to prevent the baffle plate from being too hard and scraping the belt of the food grade belt conveyor.

2. Food grade belt conveyors of different types and standard layers should not be used together, and the joints are preferably glued.

3, the food grade belt conveyor operating speed is generally not more than 2.5 m / s, large block, abrasive materials and the use of fixed pear discharge equipment should try to use low speed.

4, food grade conveyor belt should pay attention to the following matters in the operation:

A Avoid the roller being covered by the material, causing the reversal to be ineffective, avoiding the leakage of the material between the roller and the tape, paying attention to the smoothness of the moving part, but not the oil conveying tape;

B avoid loading with load;

C tape attack deviation, the application method to correct;

D It is found that the tape is partially damaged when the artificial cotton is applied, and the expansion is avoided;

E. The connection between the diameter of the conveyor roller of the conveyor and the layer of the conveyor belt, the matching of the transmission roller, the reversing drum and the groove angle of the roller should be reasonably selected according to the planning rules of the conveyor.

F. The type, structure, standard and number of layers of food grade belt conveyors should be reasonably selected according to the operating conditions.

G. When storing, the temperature of the warehouse should be maintained between 18-40 °C, and the relative humidity should be kept between 50-80%.

H. During storage, the product must be placed in rolls, not folded, and should be flipped once every season.

I Food-grade belt conveyors should be kept clean during transportation and storage to avoid direct sunlight or rain and snow immersion, avoid contact with acids, alkalis, oils, organic solvents, etc., and interval heating equipment one meter away.

In order for the food grade belt conveyor to operate for a long period of time without presenting the problem, it is necessary to pay attention to the daily protection and maintenance of the components of the food grade belt conveyor, and as such, it is possible to perform its efficient work.

2018年11月4日星期日

Reciprocating vertical lifter

#reciprocatingmotionverticalconveyor #motionverticalconveyor #verticalconveyor #verticaltypecaseconveyor #reciprocatingconveyor

Reciprocating vertical lifter -- made by Guangzhou Hongjiang Intelligent Equipment Co., LTD.

2018年11月1日星期四

Guangzhou Hongjiang Plastic Modular Belt Manufacturers

#guangzhouhongjiang #turningconveyor #modularflatturnconveyors #modularflatturnconveyorbelts #turningconveyor #modularconveyorbelt #conveyorbelt #flatmodularturningcoonveyorbelt #PVCturningconveyor

Guangzhou Hongjiang specializing in the production and supply of modular flat turn conveyors, modular flat turn conveyor belts. Guangzhou Hongjiang has developed a new turning conveyor product for the new transportation development needs of the logistics industry: modular conveyor belt turning conveyor. The radius of the inner circle does not become larger because the width of the conveyor belt becomes larger. The inner radius of the machine is only 600mm, and the 200mm step is used as the extension width. The maximum use width is 1000mm. The heavy load is up to 1 ton of cargo. The maximum speed can reach 120 meters, which can meet the high speed of logistics and other transportation of airports. Requirements are more sufficient to meet the needs of the logistics industry. The product is finished to meet various angles of transport: 30 degrees, 45 degrees, 60 degrees, 90 degrees, 120 degrees, 180 degrees turning conveyor. The flat modular turning conveyor belt not only runs stably, but also avoids the disadvantage that the general turning type modular net must be presented in a straight line segment at the transmission end due to the fixed structure design. The flat modular turning conveyor belt can replace the excess straight section design with various angles, saving mechanical manufacturing costs and making the layout of the pipeline the most space-saving operation.

The flat modular turning conveyor belt uses gear transmission, and the belt body is made of special composite steel material. At the same time, it can also develop new material products according to customers' needs, such as: strong acid and alkali resistance, high temperature resistance, low temperature resistance and antistatic. The flat modular turning conveyor belt can withstand instantaneous impact, low friction coefficient and even more than 10 times the tensile strength of the general PVC turning conveyor belt; using gear transmission, it can withstand high speed and heavy load, suitable for paper, printing, Various light and heavy load logistics such as beverages and packaging are the primary choice for customers to maintain a stable production line.

订阅:

评论 (Atom)